Normally, different silicone should be choosed according to different product's features,

- For products size (within 20cm),

with details designs, soft silicone is suitable, such as 10-20 shore A.

- For products size (20cm-80cm),

with intricate designs, 20-25 shore A is suitable.

with simple designs, 25-30 shore A is suitable.

- For products size (80cm-150cm),

with intricate designs, 25 shore A is suitable.

with simple designs, 30-35 shore A is suitable.

- For products size (more than 150cm),

with details designs, 25-28 shore a A is suitable.

with simple designs, 35-40 shore A is suitable.

Applications of Clear water Silicone

Clear water display silicone that looks just like water and is ideal for a variety of display applications.

perfect for encapsulating artificial flower stems for creating lasting floral displays.

inanimate object to encapsulate for display. create a variety of display props and novelty items.

create water/pond effects for small scale model environments.

crumbled to look like broken glass, diamonds or ice.

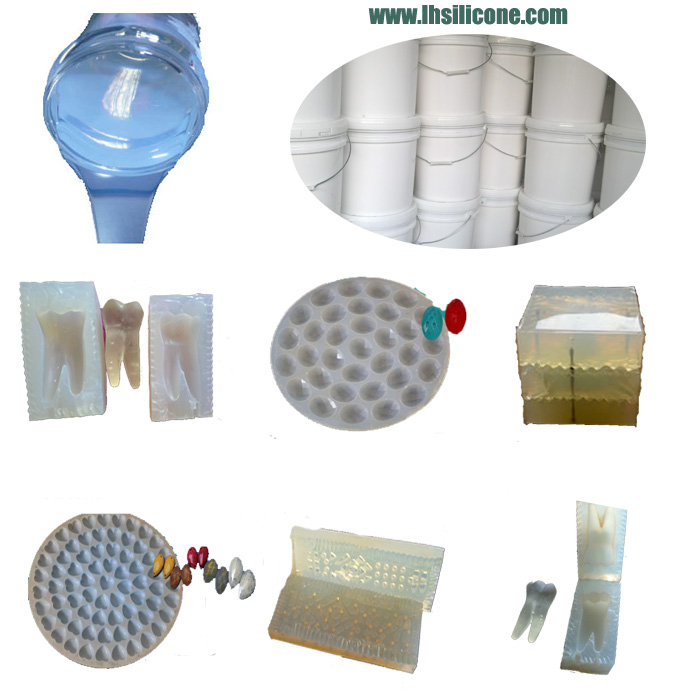

Rapid Prototype casting Silicone

mainly used for making concrete stones,

wax molds, PU molds, resin molds,

gypsum casting ,prototyping etc.

Features of RTV2 Silicone Rubber for Rapid Prototype Casting

1.flowable liquid silicone rubber and curing agent.

2.cures at room temperature within 2-4 hours.

3.Prexceptional fluidity and good operability, easy to demold.

4.good tensile and tear strength, low shrinkage.

5.with high duplication times.